What is a Submersible Pump?

The Ultimate Guide to Submersible Pumps:

Engineering, Applications, and Longevity

Submersible pumps are the unsung heroes of water management, quietly working hundreds of feet below the surface in applications ranging from your home well to massive oil and gas fields. Unlike conventional pumps, their sealed design allows them to operate entirely underwater, granting them unique mechanical advantages that make them the superior choice for deep-well applications.

This guide dives into the fundamental engineering, diverse applications, and critical maintenance strategies necessary to understand these powerful, submerged machines. By the end, you’ll know why submersible pumps push water further and last longer.

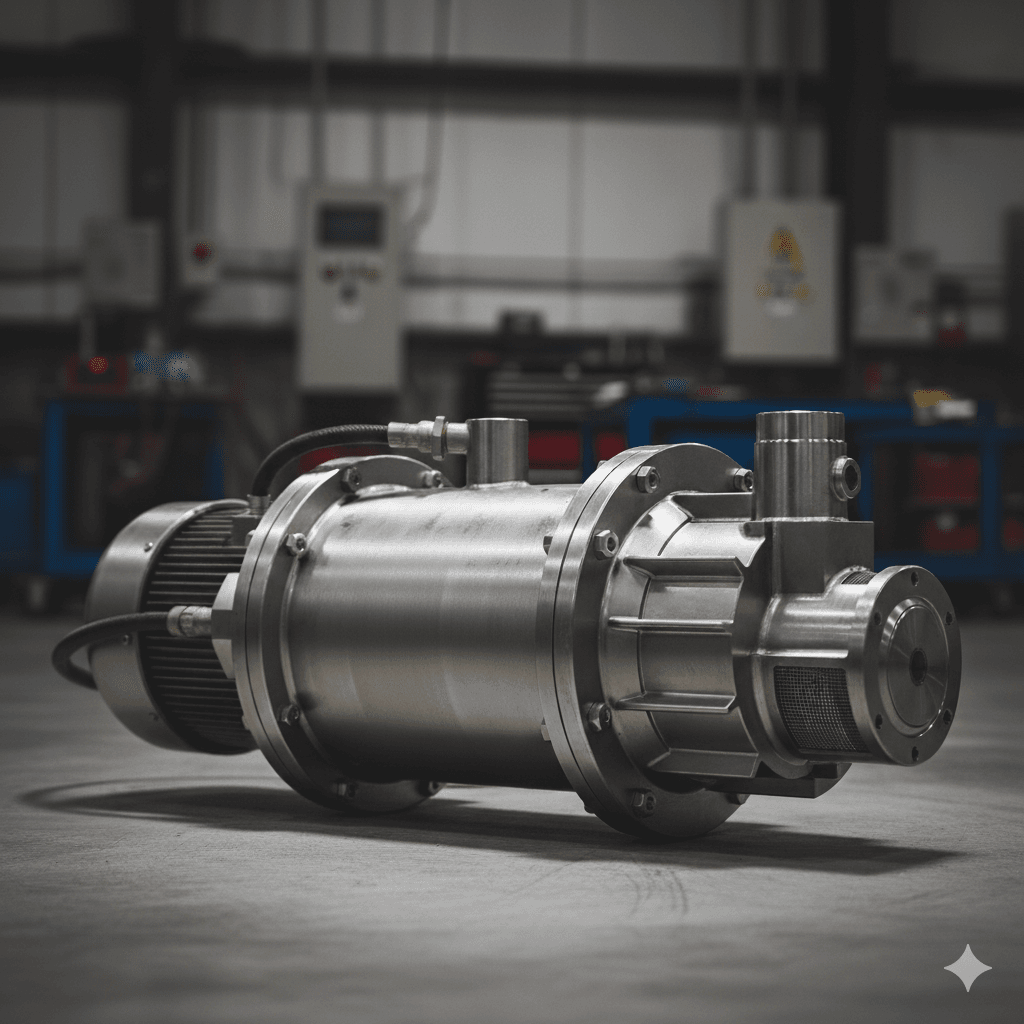

Submersible Pump

At its core, a submersible pump is defined by one key difference from a standard surface pump: it pushes the fluid rather than pulling it.

A submersible pump is a single, hermetic unit featuring a tightly sealed motor section coupled directly to the pump body. It is engineered to operate fully submerged in the fluid it is moving (water, sewage, oil, etc.).

The operational placement—fully submerged—is the source of its primary mechanical advantage. Surface pumps rely on creating a vacuum (suction) to pull water up, a process limited by atmospheric pressure to a vertical lift of only about 7 to 8 meters (approx. 25 feet). By contrast, a submersible pump utilizes the natural pressure of the surrounding fluid and pushes the column of water to the surface. This “push” mechanism overcomes the physical limitations of suction, enabling submersible pumps to reach water sources hundreds of meters below ground.

How Does the Submersible Pump Work? The Centrifugal Principle

Most commercial pumps are Electric Submersible Pumps (ESPs) that operate on the principle of multistage centrifugal force in a vertical orientation:

- Intake and Acceleration: Fluid enters through a screen at the bottom. The motor rotates a shaft connected to a series of impellers. These impellers accelerate the fluid radially, converting the motor’s mechanical energy into kinetic energy (velocity).

- Pressure Conversion: The high-velocity fluid immediately moves into a non-rotating diffuser. The vanes within the diffuser redirect the flow and, crucially, convert that kinetic energy back into potential energy, or pressure (head).

- Lifting Power: The vertical lifting capability is determined by the number of impeller and diffuser pairs—known as stages—integrated into the unit. More stages equal more pressure and a greater lifting height.

A major benefit derived from this design is the elimination of priming. Since the pump intake is always below the fluid line, the submersible pump is inherently self-priming, ensuring reliable, immediate operation without manual intervention.

Key Advantages Driving Submersible Adoption

- Extended Lifespan and Energy Savings: Because the motor is submerged, it benefits from continuous, natural cooling. This cooling prevents overheating, significantly reduces energy consumption, and extends durability. High-quality submersible pumps often last up to 20 years, double the lifespan of many surface alternatives.

- Protection from Contaminants: The fully sealed construction protects sensitive internal components and electrical parts from external contaminants like dirt, sand, and debris.

- Minimal Noise: The surrounding fluid acts as a natural sound dampener, making the submersible pump virtually silent during operation.

III. Categorizing Submersible Pump Types and Applications

Submersible pump technology is highly adaptable, leading to specialized designs for different tasks:

Residential and Municipal Solutions

- Sump Pumps: These activate when water collects, pushing the fluid out of basements or utility pits to prevent flooding.

- Effluent and Sewage Pumps: Robust units designed for wastewater, handling fluids containing substantial solids and particles from septic tanks or lift stations.

- Water Pumps: Optimized for handling clean, potable water without large particles, making them efficient for residential wells and boreholes.

Heavy-Duty Industrial Use Cases

- Dewatering Pumps: Temporary, portable solutions used on construction sites, mines, and agricultural areas to rapidly remove large volumes of standing floodwater.

- Electric Submersible Pumps (ESPs) for Oil and Gas: This highly specialized category uses multi-stage centrifugal pumps to lift complex mixtures of oil, gas, and water from extreme depths, often operating at very high speeds.

A Key Trade-Off: Pump engineering involves a direct trade-off between efficiency and particle tolerance. High-speed, high-efficiency centrifugal submersible pumps are easily damaged by sand, while robust sewage pumps must prioritize material toughness and wide clearances over maximum velocity.

Conclusion: The Strategic Value of Submersible Pumps

The submersible pump stands out as the superior, long-term solution for deep-well and heavy-duty fluid management due to its foundational mechanical design. Unlike surface pumps constrained by the physics of suction (limited to about 25 feet), the submerged placement allows these hermetically sealed units to push the fluid column, enabling them to reach sources hundreds of meters below ground. This “push” principle, powered by multistage centrifugal force, is what grants them their unmatched lifting capability.

Unmatched Efficiency and Durability

The core advantage of the submersible design is the continuous natural cooling the motor receives from the surrounding fluid. This prevents the overheating that plagues surface units, drastically lowering energy consumption and extending the pump’s operational lifespan, often to 20 years or more. Furthermore, the fully sealed construction offers inherent protection from contaminants and ensures virtually silent operation. This translates directly to a lower Total Cost of Ownership (TCO), making it the most economical choice despite a higher initial investment.

Versatility Across Critical Applications

The technology is highly versatile, with specialized designs tailored for every major fluid-handling need. From simple residential sump pumps and robust effluent/sewage pumps that handle solids, to heavy-duty dewatering pumps for construction, and complex Electric Submersible Pumps (ESPs) operating at extreme depths in the oil and gas industry, the submersible pump is an essential tool. Understanding the trade-off between efficiency (high-speed centrifugals) and particle tolerance (tough sewage pumps) is key to selecting the right unit.

Investing in Longevity

Ultimately, selecting a submersible pump is a strategic investment in reliability. By recognizing the critical role of materials and maintaining a rigorous predictive monitoring schedule—paying close attention to amperage draw and ensuring protection from dry running—owners can ensure the unit not only performs its demanding function flawlessly but also achieves its maximum potential lifespan. The submersible pump is, unequivocally, the most efficient, durable, and reliable heart of any deep-well water system.